Product Quality Is a Key Challenge for Diversifying Supply Chains

In the pursuit of diversifying their supply chains, businesses are encountering a critical challenge: ensuring product quality. Recent data reveals that as companies expand their supplier geography, they often grapple with higher rates of product defects.

Some countries, like India, have higher rates of product defects than others. However, both established sourcing hubs and less mature supplier markets can present product quality challenges. Manufacturers navigating sourcing decisions must prioritize stringent quality control measures to maintain product integrity and meet client specifications when diversifying their supply chains.

For Businesses Pursuing Diversified Supply Chains, Ensuring Product Quality Remains a Chief Concern

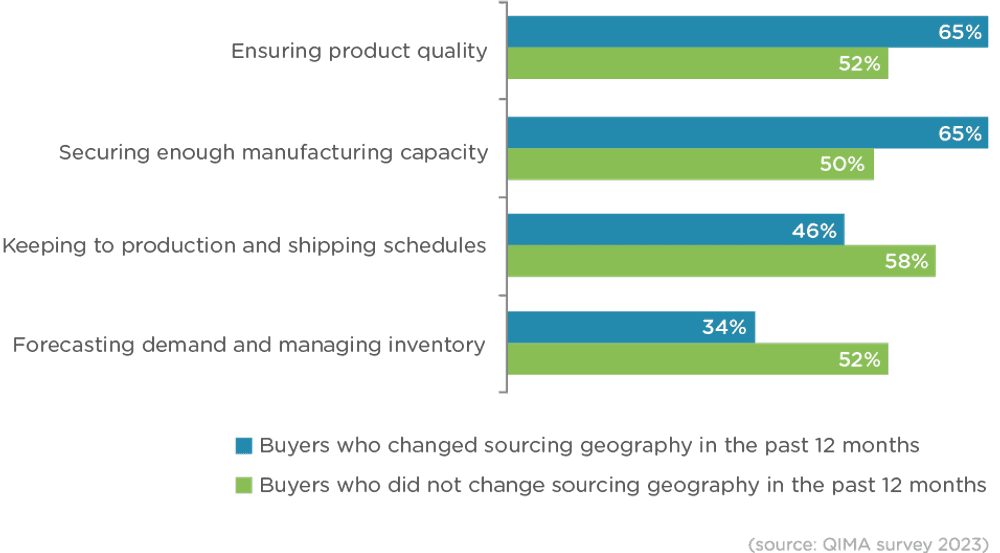

As businesses diversify their supplier base to mitigate risks and optimize their operations, the importance of maintaining product integrity remains a central concern. Of the QIMA survey respondents, 65% of buyers who changed sourcing geography in the past 12 months named ensuring product quality as a top sourcing challenge (compared to only 52% of buyers who did not change sourcing geography).

Figure 1. Top sourcing challenges named by QIMA survey respondents globally

Despite shared supply chain challenges, the leading sourcing concerns of buyers who diversified their suppliers are distinct from those who maintained their existing suppliers. The majority of buyers that diversified their suppliers in the last year are focused on ensuring product quality and securing adequate manufacturing capacity. In contrast, buyers who have not changed their sourcing geography in the last 12 months express different priorities: scheduling and inventory management. For example, 52% of buyers who did not change their sourcing report forecasting demand and managing inventory as a top sourcing challenge, compared to only 34% of buyers who did diversify. This underscores the need for tailored supply chain strategies to meet evolving priorities.

Supply Chain Diversification Impacts Product Defect Rates Across Regions

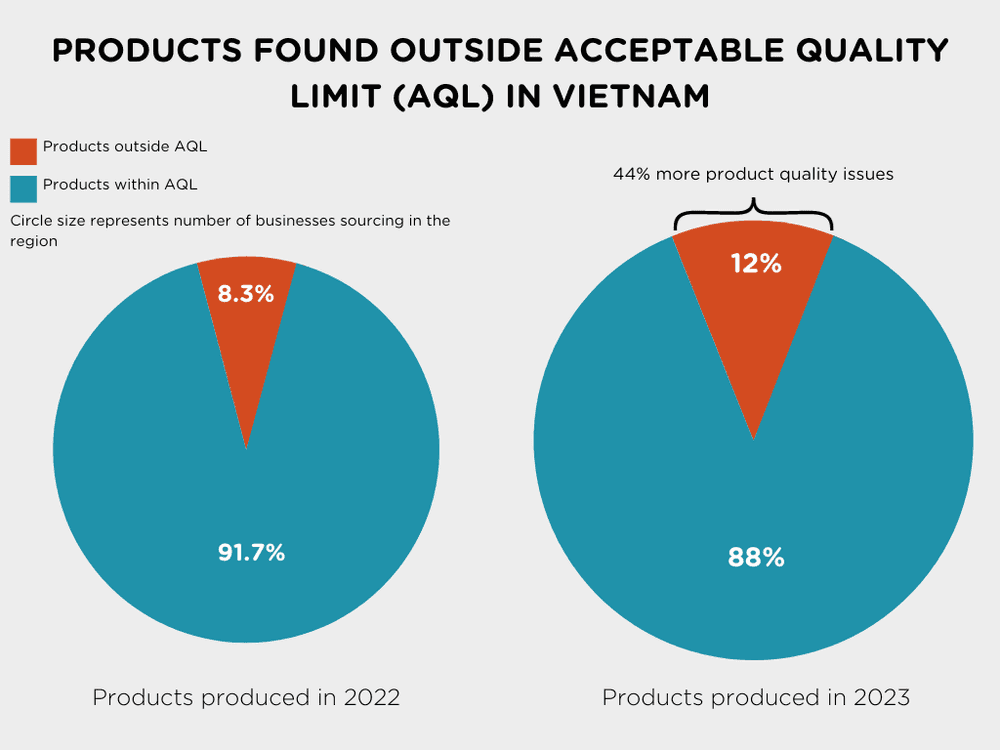

Product quality in sourcing countries can differ significantly. Generally, less mature supplier markets tend to exhibit higher rates of product defects, often falling outside the Acceptable Quality Limits (AQL).

Yet, even established sourcing hubs can face quality challenges when experiencing a surge in new business. For instance, Vietnam, traditionally a strong performer, saw a 44% year-on-year spike in "Beyond AQL" rates in the first nine months of 2023, indicating a drop in product quality. The trend extends to nearshoring markets like Mexico, where a substantial influx of business from the US led to a more than twofold increase in product defects during the same period in 2023 compared to the previous year.

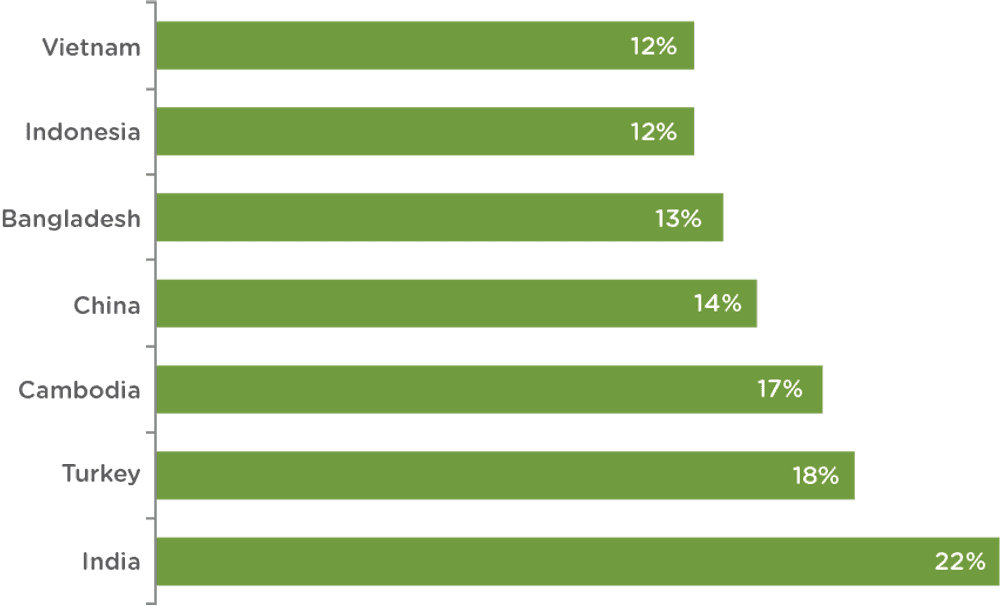

As businesses continue to diversify their supply chains, we can expect to see product quality rates fluctuate across markets. QIMA’s data reveals a complex scenario where both established and less mature sourcing markets grapple with product quality issues, highlighting the intricate interplay of factors affecting quality control. India leads the way with the highest percentage of products found outside AQL, followed by Turkey, Cambodia, China, Bangladesh, Indonesia, and Vietnam, each showing varying rates of products failing to meet client specifications.

Figure 2: Percentage of products found outside Acceptable Quality Limits, January – September of 2023 (lower value indicates better product quality)

Key Figures

QIMA’s survey of more than 250 businesses shows that:

Product quality is a key challenge for diversifying supply chains: 65% of buyers who changed sourcing geography in the last 12 months named ensuring product quality as a top sourcing challenge. 65% of buyers who changed sourcing geography also emphasized securing enough manufacturing capacity as a significant concern.

Buyers who did not change sourcing geography have different priorities: 58% named keeping to production and shipping schedules, and 52% identified forecasting demand and managing inventory as key concerns.

Supply chain diversification can lead to fluctuating product defect rates among suppliers: While less mature markets tend to have higher rates of product defects, established markets can also have high product defects if they are “overloaded” by new business.

In the first nine months of 2023, "Beyond AQL" rates spiked by 44% year-on-year in Vietnam as more businesses began sourcing in the region.

Figure 3: Percentage of products found outside Acceptable Quality Limits, January – September of 2023 (lower value indicates better product quality)

Related Articles