Guide to Food Packaging Testing Methods

Key Takeaways

Food packaging testing helps ensure that food packaging is doing its job: keeping the food safe from contamination and quality degradation.

In addition to ensuring consumer safety, food packaging testing helps ensure compliance with a variety of international food contact material regulations.

There are a variety of food packaging testing methods, including chemical testing and physical testing.

What Is Food Packaging Testing?

Food packaging testing is the process of assessing food packaging for a variety of characteristics, including safety and quality. Food packaging must keep food products safe from contamination, protect the food from damage, and maintain the food’s quality, such as flavor, smell, and texture. Testing is a critical step to ensure that food packaging is performing its intended functions effectively.

Food packaging testing includes chemical and physical tests to ensure that the packaging materials are compatible with the food they contain and that they’re able to withstand a wide range of conditions, from exposure to contaminants to jostling during shipment to high temperatures in customers’ homes. Many companies may also choose to leverage food packaging testing as they explore innovative new materials and packaging designs.

Food packaging testing helps you achieve the numerous benefits of functional, safe food packaging, including:

Consumer Safety: Any material that comes into contact with food must avoid the migration of chemicals from the packaging into the food product itself. This migration can cause the consumption of heavy metals and other toxic chemicals, as well as damage to the quality of the food.

Durable packaging that is not prone to leaks or holes is also an important safety measure, as it keeps contaminants like bacteria from touching the food. This helps keep consumers safe. Effective packaging also helps ensure that the food doesn't spoil, as eating spoiled food can also cause significant harm to consumers, especially the very young or the elderly. Different kinds of packaging materials are used to preserve the freshness of different types of foods.

Physical Protection: Effective food packaging protects the food against physical damage. For example, if an item is dropped in transit, the packaging helps to ensure that the food is not broken or squished.

Consumer Satisfaction: Food packaging is a major part of creating a unique brand image. For example, eye-catching designs or eco-friendly packaging can influence consumer purchasing decisions and increase customer loyalty. Food packaging also helps to maintain the quality of the food, which is another crucial aspect of meeting customer expectations. Customers that receive high-quality food products in perfect condition are more likely to become repeat customers.

Reduced Costs: Effective food packaging may help to reduce costs associated with overpackaging, as less material is necessary to properly protect the food. Functional food packaging will also help avoid potential recalls due to damaged or unsafe food products.

Sustainability: Today’s leaders in the food industry are increasingly making the switch to sustainable packaging, such as packaging made from recycled materials. Food packaging testing helps develop and assess new types of food packaging in order to continue prioritizing safety and quality while innovating.

Regulatory Compliance: Food packaging must comply with a number of international and domestic food safety regulations to be sold in specific markets. Major food safety regulations include ASTM standards, US FDA standards, EU directives, and food safety requirements from Australia, China, and Japan. There are a variety of food packaging testing methods, many of which are designed to ensure compliance with various safety requirements.

Types of Food Packaging

Many different materials are used for food packaging and each material type comes with specific advantages and concerns. Performing the right tests at the right time for each material is crucial for preventing potential problems.

The main types of food packaging materials include:

Metals: Metals, such as aluminum cans, are most frequently used for canned goods or beverages. While metal seals well and preserves the quality of the food or drink inside, metal packaging may be subject to corrosion if the food inside is not compatible with the metal material or coating. Often, metals are treated to prevent adverse chemical reactions between the metal and the product it contains, but testing the compatibility of the metal with its contents is crucial to ensuring safe products. Most metals are also recyclable.

Plastics: Plastic is one of the most widely used food packaging materials, and is used for everything from rigid containers to soft bags and films. While different types of plastics come with different risks, one of the major concerns of plastic is chemical leaching (migration) of the chemicals used in plastic packaging into the food. Migration testing and durability testing are crucial for plastic packaging. Some plastics may also allow gasses to leak into the packaging even without leaks. Another common concern is that plastic is not a sustainable material, as it's made from fossil fuels. Despite these concerns, plastic is popular for its versatility and its protection against contamination.

Glass: Glass is one of the lesser-used food packaging materials due to its extreme fragility, which makes it difficult to transport. Glass does have several benefits, however, including its low-reactivity with foods, its reusability, and its protection against contaminants including microbes and gasses.

Paper, paperboard, and cardboard: Paper and cardboard packaging are more cost-effective food packaging material options, and are often recyclable or biodegradable. However, these materials are less protective than others, as they are not air-tight or waterproof. Testing for paper-based food packaging ensures the packaging can withstand a variety of potential environmental conditions and physical wear and tear.

Food Packaging Testing Methods

There are numerous food packaging testing methods, with each method designed to assess a specific characteristic of the packaging. As discussed above, different types of packaging materials will require different testing. The goal of all of the following food packaging testing methods is to ensure the packaging works as intended and is adequately protective to keep the food fresh and safe.

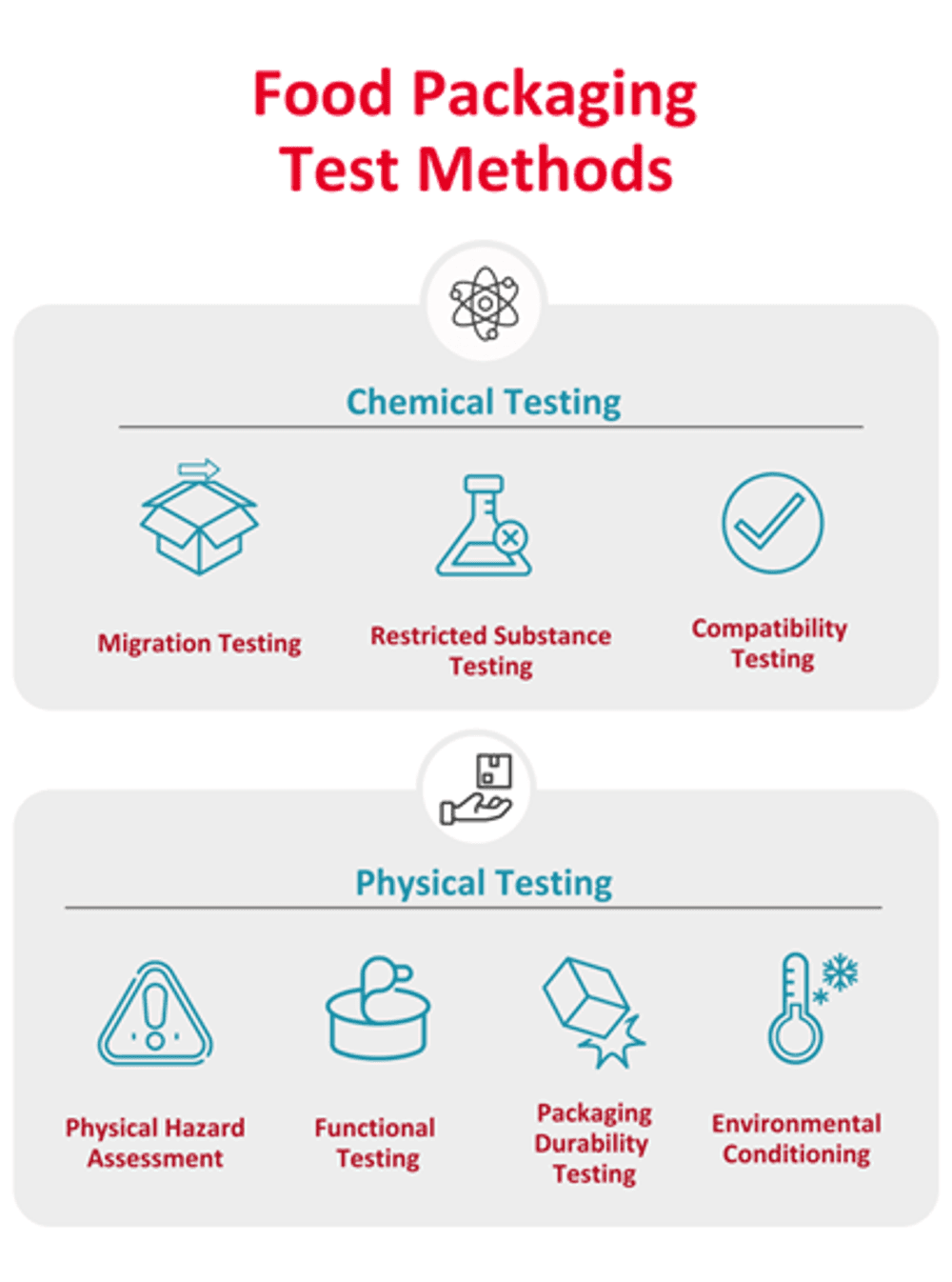

Generally, food packaging testing methods can be split into chemical testing and physical testing.

Chemical Food Packaging Testing Methods

Chemical food packaging testing focuses on the chemical structure of the material and seeks to examine how the chemical composition of a packaging material affects its interactions with food. Any material that comes into contact with food must undergo chemical testing in order to avoid adverse reactions.

Migration Testing

Migration is the process by which chemicals are transferred from the food packaging to the food itself. Migration of toxic chemicals into food can harm human health, especially at high exposures. Migration testing in food packaging is a method that quantifies the amount of chemical substances that are transferred from packaging to food in order to protect consumers from exposure to harmful chemicals. Migration testing also helps ensure compliance with regulatory migration limits.

Depending on the product and destination market, you may require specific migration testing and overall migration testing. Specific migration refers to the transfer of specific substances from food packaging materials into the food or beverage contained within, potentially leading to contamination. On the other hand, overall migration refers to the overall transfer of all substances present in food packaging materials into the food or beverage, including both intentional additives and unintended contaminants. For example, specific migration testing of phthalates measures the transfer of phthalates from food packaging materials into the food or beverage.

Read more about migration testing and other requirements in the EU: Understanding New EU Food Contact Material Regulations

Restricted Substance Testing

Restricted substance testing detects the presence of substances in food packaging that are restricted by international regulations. Restricted substance testing focuses on the chemical composition of the packaging itself, rather than measuring the transfer of chemicals to food, as migration testing does.

Substances that are restricted in food packaging and that are often the subject of testing include BPA, lead, and heavy metals, although restricted substances vary by destination market. Testing is a crucial component of compliance, as it ensures these substances are not present at levels above those allowed by regulations.

Compatibility Testing

Compatibility testing is used to evaluate the compatibility of a food packaging material with the food inside to ensure that the materials don’t interact in a way that compromises product safety or quality. The goal is to analyze the active substances of both the packaging and the food to determine:

Whether the packaging and food undergo adverse chemical reactions

Whether the package adequately protects the food from spoiling or other changes

In compatibility testing, the packaging with the food product inside is exposed to a range of temperatures to assess reactions under a number of different conditions.

Physical Food Packaging Testing Methods

Physical food packaging testing assesses the physical characteristics of the packaging. Physical testing helps manufacturers ensure that their packaging is easy and safe to use, durable, and able to withstand a variety of environmental conditions.

Functional Testing

These tests aim to ensure that the packaging can be used as intended. For example, functional testing may include sticking a straw through a perforated opening in a juice carton, ensuring that handles are strong enough to carry the package, or ensuring that a can may be opened using the ring pull. Packaging functionality is a major aspect of maintaining customer satisfaction.

Packaging Strength and Durability Testing

There are many physical testing methods designed to examine the durability of packaging and its ability to withstand wear and tear. Many of these tests are designed to make sure that the packaging will continue to protect the product during shipment, when the product may be handled roughly. These include:

Compression tests: The packaging is squeezed to understand how much compression it can withstand. This helps assess the packaging’s durability, particularly as it relates to how many packages can be stacked on top of each other before the product’s quality is damaged.

Drop tests: The packaging is dropped on its flat surface or its edges or corners to mimic potential drops it may experience during transport. Packaging may also undergo vibration testing, which is similar, as it tests the ability of the packaging to withstand vibration that might occur during transport.

Environmental Conditioning

Environmental conditioning for food packaging helps to ensure that the product can withstand a variety of environmental conditions, particularly those that the product will face during distribution. This method of testing involves exposing the product to several specific environmental conditions, including high or low temperatures or high humidity. For example, this type of testing includes microwave and freezer safety testing, thermal shock testing, and heat exposure. Exposure to varied environmental conditions is also used in several food packaging testing methods, such as compatibility testing and seal integrity testing.

Physical Hazard Assessment

This type of testing involves assessing the physical hazards a person may face when opening or using the package. Physical hazards resulting from food packaging may include burns and suffocation or other airway obstructions. While this is not an issue for all types of food packaging, physical hazard assessments are an important aspect of risk reduction. Physical hazard assessments also help you avoid recalls and even lawsuits in the future.

How QIMA Can Help

QIMA’s rich industry experience and team of experts can help you take charge of your product compliance for food containers and packaging products. As a leading provider of quality control, lab testing, and audit services for global markets, we are always keeping up with the current state of regulations and can help you navigate complex and evolving requirements.

QIMA’s seasoned experts can test every element of your food contact materials for non-compliance, including overall migration testing and heavy metal migration testing. Other chemical tests we offer include:

Specific migration of phthalates

Extractable lead & cadmium

Migration of specific heavy metals

Specific migration of melamine

Metal composition

Bisphenol A content

In addition to chemical tests, we conduct physical testing including:

Drop impact

Microwave safety

Corrosion resistance

Heat exposure

Thermal shock

Surface scratching

Boil-dry

Acid resistance

Freezer safety

Coating adhesion

Contact us today and we’ll be happy to help you make sure your food packaging items are compliant.

Related Articles