Your 2025 Peak Season Playbook: Beat the Tariff Chaos

Peak season brings intensified pressure on operations and product delivery for retailers, brands, and manufacturers to meet heightened consumer demands for the upcoming holiday period. The expiration of the U.S. government's pause on reciprocal tariffs in July 2025, combined with ongoing geopolitical and economic uncertainties, means supply chains are facing big challenges.

Michael Bland, Senior Sales Director at QIMA emphasizes that, “Peak season exposes every weak link in your supply chain. Robust quality and compliance systems, built proactively with all stakeholders, are not just about fixing issues—they ensure your brand delivers consistently, no matter the pressure.” This approach ensures your brand reputation remains strong, with high-quality, compliant products delivered on time, even during the most demanding production cycles.

QIMA’s Q3 2025 barometer shows:

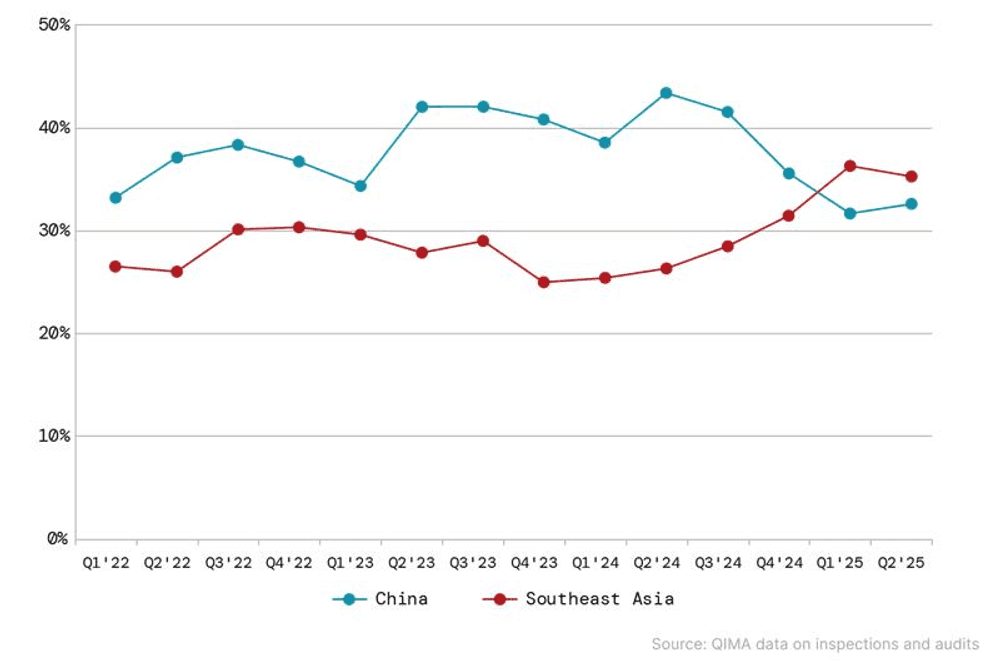

US businesses are ordering 24% fewer inspections in China compared to last year, while demand in Southeast Asia is up 29%. (Fig. 1 Relative shares of China and Southeast Asia in US sourcing – quarterly trend)

European buyers are still getting toys from China but they're increasingly looking at places like Morocco (+53%) and Egypt (+73%) for textiles.

The changes ahead mean your business needs a game plan. Our guide will show you how to prepare, keep your product quality high, and meet consumer expectations.

Fig. 1 Relative shares of China and Southeast Asia in US sourcing – quarterly trend

Build a Resilient and Flexible Supplier Network

With new tariffs causing disruptions, building a resilient and flexible supplier network is crucial for navigating peak season challenges. The Q3 2025 barometer highlights significant sourcing shifts: US businesses have reduced inspections in China by 24% while increasing demand in Southeast Asia by 29%, with Vietnam and Thailand becoming key hubs for toys and textiles. European buyers, meanwhile, are expanding textile sourcing to Mediterranean countries like Morocco and Egypt, where inspection demands have surged by 53% and 73%, respectively.

To mitigate risks from tariffs and regional disruptions, businesses should diversify their supplier bases across multiple regions and build trust through collaboration with suppliers, retailers, and auditors—a strategy prioritized by 45% of companies.

For instance, a US toy manufacturer successfully avoided tariff impacts by qualifying suppliers in Vietnam ahead of time, while a European apparel brand maintained production continuity by leveraging pre-audited suppliers in Morocco during challenges in Turkey.

Tactic: Conduct comprehensive supplier audits in alternative regions like Vietnam for toys and Cambodia for textiles, evaluating capacity and tariff resilience. Set standardized self-inspection protocols.

Payoff: A diversified supplier base minimizes disruptions from tariff hikes or regional instability, ensuring consistent production during peak season.

Quality Control: The Foundation of Brand Reputation

Peak season amplifies the risk of quality lapses and compliance failures. However, a proactive, data-driven quality control program—not just reactive checks—safeguards your brand. For toys, adherence to EU safety standards is critical, particularly given the 24% year-over-year increase in inspection demand in China.

In textiles, sustainability and durability are becoming increasingly important as consumers demand eco-friendly products. Proactive quality control starts early, using data-driven systems like supplier self-inspections and pre-season audits. This is then followed by testing of product samples in accredited laboratories and then in-line and pre-shipment inspections to identify defects before shipping.

Christopher Wheeler, QIMA’s General Manager for Inspections, advises that "Carrying out inspections early in production is a critical strategy during peak season, preventing quality failures and safeguarding consumer trust". Third-party providers like QIMA can conduct on-site inspections within 48 hours, offering quick insights to prevent costly delays.

For example, in-line inspections helped a textile manufacturer avoid a major recall in 2024 by catching stitching defects early in the production process, saving millions in potential losses.

Tactic: Schedule pre-production, in-line, and pre-shipment inspections with third-party support.

Payoff: Early defect detection prevents recalls, reduces financial risks, and maintains customer trust.

Leveraging Technology for Proactive Risk Management

Today’s sourcing environment comes with risks that go far beyond tariffs, including port congestion, labor disputes in manufacturing hubs like Bangladesh, and weather-related disruptions in Southeast Asia.

Advanced technology, such as AI-driven tools like QIMA Risk Radar, predict disruptions using real-time and historical data, aiding decisions.

For instance, predictive analytics can forecast the impact of tariff increases on sourcing costs, allowing you to adjust supplier allocations proactively. Centralized digital platforms, such as QIMA’s dashboards, provide immediate access to quality checks, compliance audits, and lab test results, making it easier to make fast decisions under tight peak-season timelines.

In 2024, a European retailer used these tools to quickly reroute textile shipments from Bangladesh to Thailand amid labor unrest, avoiding significant delays.

Tactic: Implement AI-driven risk management tools to monitor real-time disruptions, such as tariff impacts or port delays, and use centralized dashboards for efficient data access.

Payoff: Pivot before the chaos hits, to adapt smoothly to unexpected challenges.

Ethics and Sustainability: Building Consumer Trust

Consumer demand for ethical and sustainable products is reshaping industries. In the toy industry, meeting safety and chemical standards is crucial, while textile brands face increasing pressure to improve working conditions and minimize their environmental impact. Conducting regular sustainability audits ensures suppliers adhere to fair labor standards, environmental regulations, and eco-friendly production methods, such as reducing water usage in textile manufacturing.

Training suppliers in compliance with requirements and offering incentives, such as preferred contracts, encourages the adoption of sustainable practices. Transparent communication, through public sustainability reports, builds consumer trust, as 68% of shoppers consider ethical practices a key factor in their purchasing decisions (McKinsey, 2025).

A toy manufacturer boosted brand loyalty in 2024 by highlighting its chemical-free production processes, gaining a competitive edge.

Tactic: Conduct sustainability audits and train suppliers on compliance. Incentivize eco-friendly practices and share progress through transparent reporting.

Payoff: Enhanced brand reputation and customer loyalty differentiate your business in a competitive market.

Preparing for Peak Season: A Proactive, Coordinated Approach

To make the most of the peak season, you need a clear plan to handle tariff uncertainties and sourcing shifts. It is not about scrambling to fix problems as they arise—it's about building and maintaining robust systems and processes, grounded in data and teamwork, long before the pressure mounts.

By strengthening supplier relationships, prioritizing quality control, leveraging technology for risk management, diversifying supplier bases, and committing to ethical practices, you can successfully overcome challenges and capitalize on peak demand.

QIMA provides comprehensive support to help you stay prepared, from quick, on-the-ground inspections to real-time, AI-powered risk monitoring. Want to optimize your supply chain strategy this peak season? Schedule a consultation with QIMA's experts and get tailored guidance for your business.

Related Articles